DALWORTH SUPERMILL

DALWORTH MACHINE PRODUCTS, INC

Call us: (817)561-9802

®

| ||||||

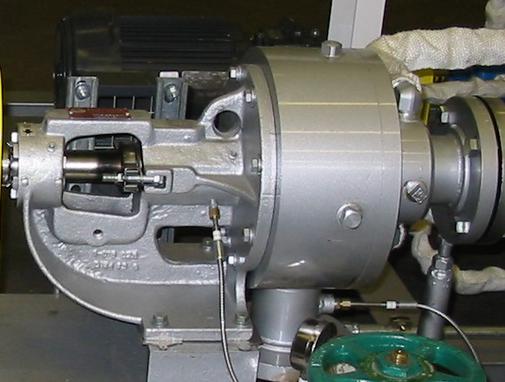

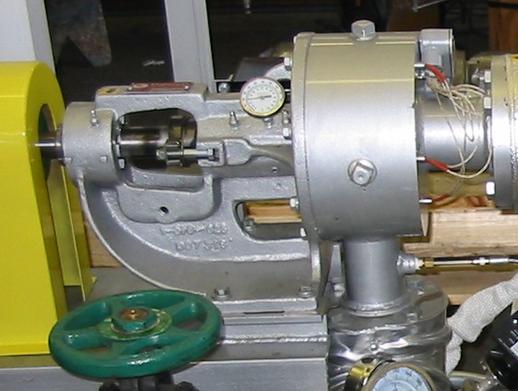

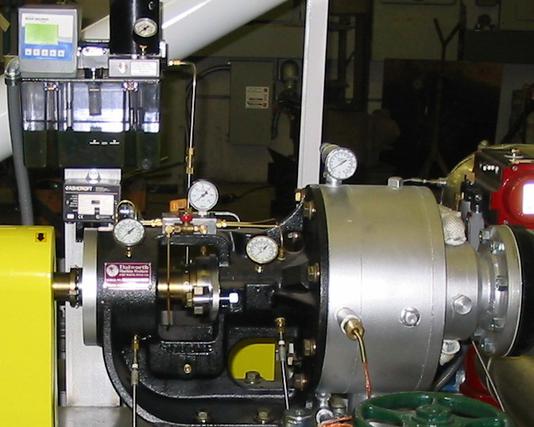

MP-10SB-M BLENDING MILL

DALWORTH MACHINE PRODUCTS

KNOWN AROUND THE WORLD FOR SUPERIOR COLLOID MILLS

THE DALWORTH DIFFERENCE!!

When making MODIFIED ASPHALTS,

THE DALWORTH BLENDING MILLS CAN MAKE POLYMER MODIFIED ASPHALT UP TO 17% CONCENTRATED IN A SINGLE PASS!!!

THEN CONCENTRATED PMA CAN BE CUTBACK WITH NEAT ASPHALT TO YIELD

4 TIMES THE PRODUCT PER HOUR THAT THE MILL IS RATED FOR.

We take pride in our wide selection of quality colloid mills. All of the mills we offer are made IN THE USA, in our shop and are delivered to you with the added benefit of many years of experience in the asphalt industry to help you work through the difficult process of competing in today's asphalt markets. We make EMULSION MILL in all sizes from 2 GPM to 400 GPM. We make POLYMER MODIFIED ASPHALT BLENDING MILLS to produce from 1 GPM to 250 GPM in a single pass. We also make COMBINATION MILLS that produce both ASPHALT EMULSION and POLYMER MODIFIED ASPHALT.

If you have any questions regarding our mills or would like more information, please contact us:

NU-8SB BLENDING MILL

NU-4SB BLENDING MILL

NU-3SB BLENDING MILL

DALWORTH "SUPERMILLS"

Building the GREAT MILLS at a GREAT VALUE is our top priorities.

TOP SELLING BLENDING MILL

Specifications:

• Max. Flow: 4,000 GPH ( up to 17% PMA Concentate)

Max. Flow: 4,000 GPH ( up to 17% PMA Concentate)

• Production Range: (5-15 MTPH)

• Shear surfaces per minute: 1.3 million

• Shear Force: 101,736 sfm

• Temperature: 50° to 300°F

Temperature: 50° to 300°F

• Lubrication: Litium Complex Grease

Lubrication: Litium Complex Grease

• Max. Power: 100 HP

Max. Power: 100 HP

• Min. Power : 60 HP

Min. Power : 60 HP

• Speed: 3600 rpm

Speed: 3600 rpm

• Materials of Construction:

Materials of Construction:

o All shear plates 17-4 Stainless Steel

All shear plates 17-4 Stainless Steel

o All Housing/Piping Carbon Steel

All Housing/Piping Carbon Steel

• Supply Connections: 3” x 150 LB RF Flange

Supply Connections: 3” x 150 LB RF Flange

• Discharge Connection: 2 ½” x 150 LB RF Flange

Discharge Connection: 2 ½” x 150 LB RF Flange

• Bearings:

Bearings:

o SKF Precision Cylindrical Roller

SKF Precision Cylindrical Roller

o SKF Double Roller Thrust

SKF Double Roller Thrust

• Seals:

o Garlork HD Viton

Garlork HD Viton

o Chesterton Graphite/ Carbon adjustable Packing

Chesterton Graphite/ Carbon adjustable Packing

• OPTIONAL FEATURES:

o Sensors for automation controls

o Closed Loop cooling system

o Duel Sealed pressurized Barrier Fluid:

w/ Chesterton Mechanical seal - rated to 300PSI

o Optional Lubrication: Automated / Self Regulating cycle time

Specifications:

• Max. Flow: 5,000 GPH ( up to 17% PMA Concentate)

Max. Flow: 5,000 GPH ( up to 17% PMA Concentate)

• Production Range: (10-20 MTPH)

• Shear surfaces per minute: 1.3 million

• Shear Force: 113,040 sfm

• Temperature: 50° to 400°F

Temperature: 50° to 400°F

• Lubrication: ISO 150 Oil

Lubrication: ISO 150 Oil

• Max. Power: 200 HP

Max. Power: 200 HP

• Min. Power : 150 HP

Min. Power : 150 HP

• Speed: 3600 rpm

Speed: 3600 rpm

• Materials of Construction:

Materials of Construction:

o All shear plates 17-4 wear resistant Stainless Steel

All shear plates 17-4 wear resistant Stainless Steel

o All Housing/Piping Carbon Steel

All Housing/Piping Carbon Steel

• Supply Connections: 4” x 150 LB RF Flange

Supply Connections: 4” x 150 LB RF Flange

• Discharge Connection: 3” x 150 LB RF Flange

Discharge Connection: 3” x 150 LB RF Flange

• Bearings:

Bearings:

o SKF Precision Cylindrical Roller

SKF Precision Cylindrical Roller

o SKF Double Roller Thrust

SKF Double Roller Thrust

• Dual Sealed pressurized Barrier Fluid:

o Garlork HD Viton

Garlork HD Viton

o Chesterton Mechanical seal -

Chesterton Mechanical seal -

(rated to 300PSI)

• Lubrication: Automated / Self Regulating Oil InjectionSystem with adjustable flow rates & cycle time

Lubrication: Automated / Self Regulating Oil InjectionSystem with adjustable flow rates & cycle time

• OPTIONAL FEATURES:

o Sensors for automation controls

o Closed Loop cooling system

Specifications:

• Max. Flow: 2,400 GPH PMA

Max. Flow: 2,400 GPH PMA

• Production Range: (10 MTPH)

• Shear surfaces per minute: 1.3 million

• Shear Force: 90,432 sfm

• Temperature: 50° to 300°F

Temperature: 50° to 300°F

• Lubrication: Litium Complex Grease

Lubrication: Litium Complex Grease

• Max. Power: 75 HP

Max. Power: 75 HP

• Min. Power : 50 HP

Min. Power : 50 HP

• Speed: 3600 rpm

Speed: 3600 rpm

• Materials of Construction:

Materials of Construction:

o All shear plates 17-4 wear resistant Stainless Steel

All shear plates 17-4 wear resistant Stainless Steel

o All Housing/Piping Carbon Steel

All Housing/Piping Carbon Steel

• Supply Connections: 3” x 150 LB RF Flange

Supply Connections: 3” x 150 LB RF Flange

• Discharge Connection: 2 ½” x 150 LB RF Flange

Discharge Connection: 2 ½” x 150 LB RF Flange

• Bearings:

Bearings:

o SKF Precision Cylindrical Roller

SKF Precision Cylindrical Roller

o SKF Double Roller Thrust

SKF Double Roller Thrust

• Seals:

o Garlork HD Viton

Garlork HD Viton

o Chesterton Graphite/ Carbon adjustable Packing

Chesterton Graphite/ Carbon adjustable Packing

• OPTIONAL FEATURES:

o Sensors for automation controls

o Closed Loop cooling system

o Duel Sealed pressurized Barrier Fluid:

w/ Chesterton Mechanical seal - rated to 300PSI

o Optional Lubrication: Automated / Self Regulating cycle time

CONTACT US FOR MORE OPTIONS AVAILABLE FOR THIS MODEL >

Specifications:

• Max. Flow: 1,200 GPH PMA

Max. Flow: 1,200 GPH PMA

• Production Range: (5 MTPH)

• Shear surfaces per minute: 800,000

• Shear Force: 85,254 sfm

• Temperature: 50° to 400°F

Temperature: 50° to 400°F

• Lubrication: ISO 150 Oil

Lubrication: ISO 150 Oil

• Max. Power: 25 HP

Max. Power: 25 HP

• Min. Power : 15 HP

Min. Power : 15 HP

• Speed: 3600 rpm

Speed: 3600 rpm

• Materials of Construction:

Materials of Construction:

o All shear plates 17-4 wear resistant Stainless Steel

All shear plates 17-4 wear resistant Stainless Steel

o All Housing/Piping Carbon Steel

All Housing/Piping Carbon Steel

• Supply Connections: 2” x 150 LB RF Flange

Supply Connections: 2” x 150 LB RF Flange

• Discharge Connection: 1 1/2” x 150 LB RF Flange

Discharge Connection: 1 1/2” x 150 LB RF Flange

• Bearings:

Bearings:

o SKF Precision Cylindrical Roller

SKF Precision Cylindrical Roller

o SKF Double Roller Thrust

SKF Double Roller Thrust

• Seals:

Seals:

o Garlork HD Viton

Garlork HD Viton

o Chesterton Graphite/ Carbon adjustable packing

Chesterton Graphite/ Carbon adjustable packing

• OPTIONAL FEATURES:

o Sensors for automation controls

o Closed Loop cooling system

o Duel Sealed pressurized Barrier Fluid:

w/ Chesterton Mechanical seal - rated to 300PSI

o Optional Lubrication: Automated / Self Regulating cycle time

Specifications:

• Max. Flow: 17,000 GPH ( UP TO 17% PMA Concentrate)

Max. Flow: 17,000 GPH ( UP TO 17% PMA Concentrate)

• Production Range: (40-80 MTPH)

• Shear surfaces per minute: 3.6 million

• Shear Force: 135,648 sfm

• Temperature: 50° to 400°F

Temperature: 50° to 400°F

• Lubrication: ISO 150 Oil

Lubrication: ISO 150 Oil

• Max. Power: 300 HP

Max. Power: 300 HP

• Min. Power : 250 HP

Min. Power : 250 HP

• Speed: 3600 rpm

Speed: 3600 rpm

• Materials of Construction:

Materials of Construction:

o All shear plates 17-4 wear resistant Stainless Steel

All shear plates 17-4 wear resistant Stainless Steel

o All Housing/Piping Carbon Steel

All Housing/Piping Carbon Steel

• Supply Connections: 4” x 150 LB RF Flange

Supply Connections: 4” x 150 LB RF Flange

• Discharge Connection: 4” x 150 LB RF Flange

Discharge Connection: 4” x 150 LB RF Flange

• Bearings:

Bearings:

o SKF Precision Cylindrical Roller

SKF Precision Cylindrical Roller

o SKF Double Roller Thrust

SKF Double Roller Thrust

• Dual Sealed pressurized Barrier Fluid:

o Garlork HD Viton

Garlork HD Viton

o Chesterton Mechanical seal - (rated to 600PSI)

Chesterton Mechanical seal - (rated to 600PSI)

• Lubrication: Automated / Self Regulating Oil InjectionSystem with adjustable flow rates & cycle time

Lubrication: Automated / Self Regulating Oil InjectionSystem with adjustable flow rates & cycle time

• OPTIONAL FEATURES:

o Sensors for automation controls

o Closed Loop cooling system

CM-9SB-M BLENDING MILL

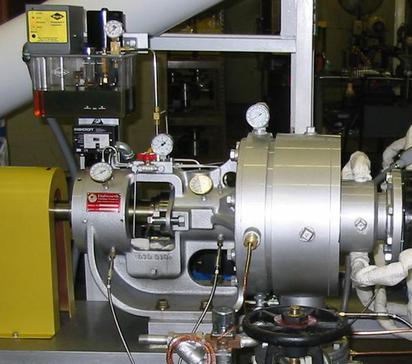

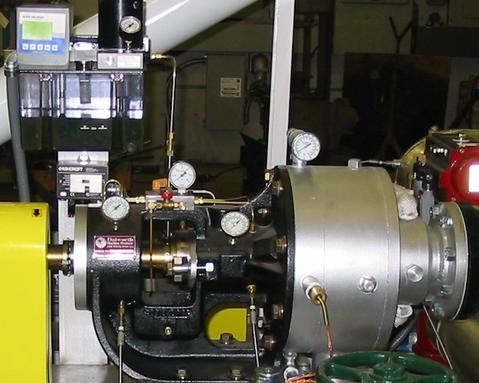

MP-11SB-M BLENDING MILL

Specifications:

• Max. Flow: 8,000 GPH ( up to 17% PMA Concentate)

Max. Flow: 8,000 GPH ( up to 17% PMA Concentate)

• Production Range: (10-45 MTPH)

• Shear surfaces per minute: 1.3 million

• Shear Force: 113,040 sfm

• Temperature: 50° to 400°F

Temperature: 50° to 400°F

• Lubrication: ISO 150 Oil

Lubrication: ISO 150 Oil

• Max. Power: 250 HP

Max. Power: 250 HP

• Min. Power : 150 HP

Min. Power : 150 HP

• Speed: 3600 rpm

Speed: 3600 rpm

• Materials of Construction:

Materials of Construction:

o All shear plates 17-4 wear resistant Stainless Steel

All shear plates 17-4 wear resistant Stainless Steel

o All Housing/Piping Carbon Steel

All Housing/Piping Carbon Steel

• Supply Connections: 4” x 150 LB RF Flange

Supply Connections: 4” x 150 LB RF Flange

• Discharge Connection: 3” x 150 LB RF Flange

Discharge Connection: 3” x 150 LB RF Flange

• Bearings:

Bearings:

o SKF Precision Cylindrical Roller

SKF Precision Cylindrical Roller

o SKF Double Roller Thrust

SKF Double Roller Thrust

• Dual Sealed pressurized Barrier Fluid:

o Garlork HD Viton

Garlork HD Viton

o Chesterton Mechanical seal -

Chesterton Mechanical seal -

(rated to 300PSI)

• Lubrication: Automated / Self Regulating Oil Injection System with adjustable flow rates & cycle time

Lubrication: Automated / Self Regulating Oil Injection System with adjustable flow rates & cycle time

• OPTIONAL FEATURES:

o Sensors for automation controls

o Closed Loop cooling system

CONTACT US FOR MORE OPTIONS AVAILABLE FOR THIS MODEL >

CONTACT US FOR MORE OPTIONS AVAILABLE FOR THIS MODEL >

CONTACT US FOR MORE OPTIONS AVAILABLE FOR THIS MODEL >

CONTACT US FOR MORE OPTIONS AVAILABLE FOR THIS MODEL >

CONTACT US FOR MORE OPTIONS AVAILABLE FOR THIS MODEL >